Our techniques

Handley’s traditional printing experience, together with the latest technologies suits both classical and modern needs of our clients.

Whether it's for you or your business, all our printing techniques can meet your most creative desires and ideas.

Each project is tailor-made and can be highlighted using the right paper and the right technique.

Printing technique where a Pantone matt color (U = uncoated, reference for uncoated paper) is printed on the paper and may or may not be pushed through.

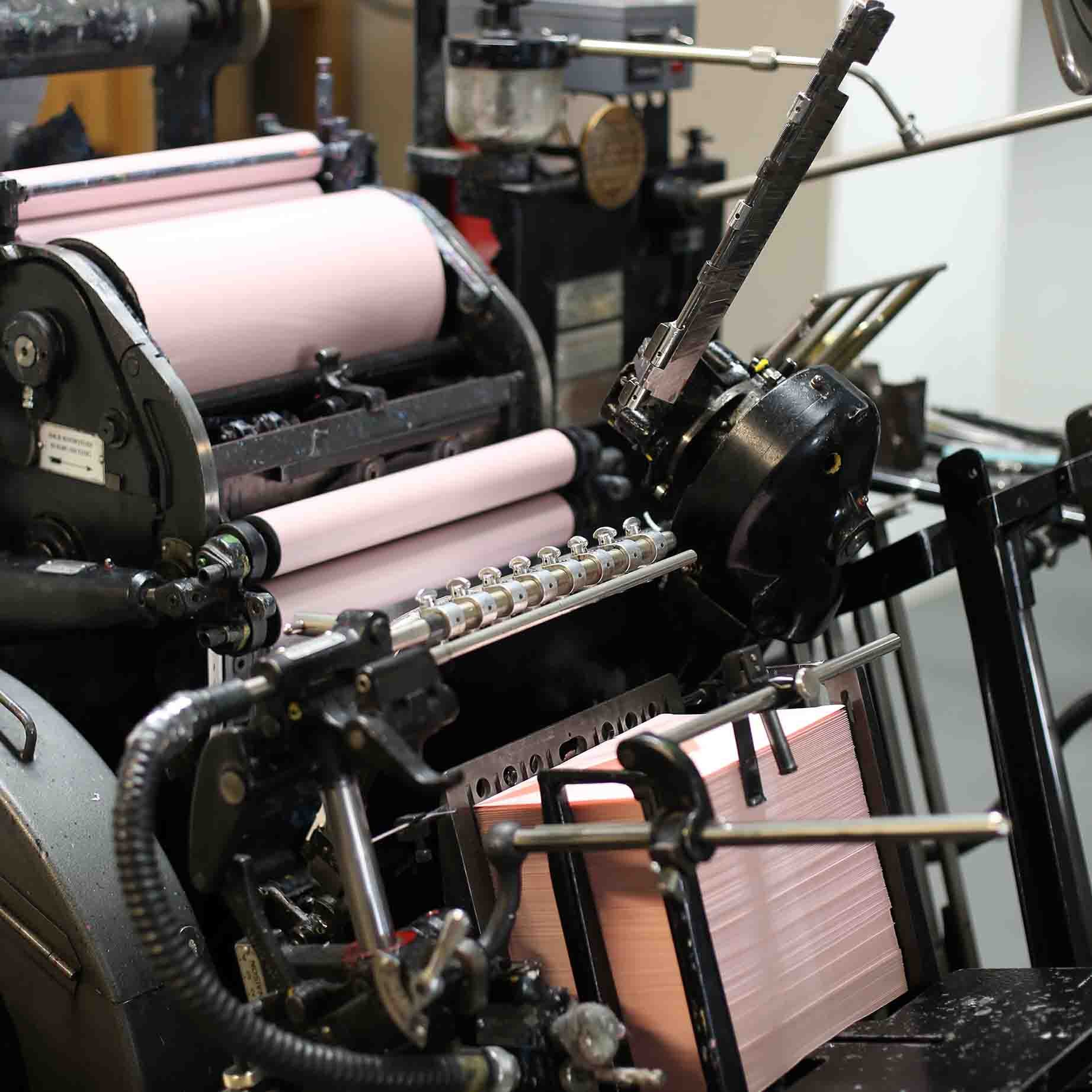

typography - letterpress

-

The cliché is made of polymer and allows this pressure to be applied. The number of colors that can be produced is therefore infinite. We can also create your own colors 100 % home made. This technique can be applied to 300g paper, but it will mark the backside of it. If you're working on a double-sided project, you will need to use a thicker paper (600g or more) or use a double format. This printing technique can also be done without ink. Making the motif or text discreet.

Paper: uncoated from 90g to 700g, the puffier the paper, the more pressure will be felt on your project.

Files to be received: full-size pdf with cut lines and 3 mm bleeds, 1 page per color printed exported in 100% black (C0 M0 Y0 K100).

Hot foil is a printing process in which a metallised film is heated on the paper using a magnesium cliché. The colors of the film are various and can add fun to your project (gold, rose gold, copper, holographic, starry, etc.).

hot foil

-

The type is lightly pressed into the paper by means of a magnesium plate in relief. Thanks to this printing technique, we can achieve a very high degree of finesse on the printed characters or illustrations.

Thanks to the opacity of the films, this technique is ideal for printing on dark cardboard, to enhance an invitation with a glossy touch, or to add sparkle to packaging. Thanks to this technique, white printing is also possible.

Paper: coated or uncoated, up to 900g. The line cannot be finer than 0.08 mm or 0.25 pt.

Files to be supplied: full-size pdf with cut lines and 3 mm bleed, 1 page per film color required, exported in 100% black (C0 M0 Y0 K100).

This printing technique (also known as inked stamping) is the oldest and most traditional. Each card is passed by hand, one by one, through the stamping machine, which engraves a pattern/text on the paper. This pattern is then printed on the back of the paper.

engraving

-

This printing process produces fine lines and ink relief of unrivalled quality. For highly detailed motifs, the engraving blocks are still made by hand by artisan engravers. A matt or glossy ink is deposited in the hollows of an engraving block made of chromed steel or copper. Re-engraving, an additional manual passage through the machine, gives even greater brilliance to the engraved motif.

This high-quality process is ideal for both private and business stationery, as the engraving blocks can be reused on a variety of substrates and formats (e.g. letterhead and envelope flaps).

Handley has a wide range of initials engraving blocks that can be used for wedding invitations, birth announcements, invitations, ...

Papers: uncoated from 90 gr to 700 gr

Files to be received: full-size pdf with cut lines and 3 mm bleeds, 1 page per color printed exported in 100% black (C0 M0 Y0 K100).

The embossing printing process is a relief print - without ink - that stands out (or in) from the paper. It is only the play of shadows that makes the motif stand out.

embossing & debossing

-

Here, the reverse side of the paper is also clearly marked. This is because there is a male and female part that fit together, so that when you look at the print on both sides, you can see what it is. Since one part has to fit inside the other, the pattern is generally thicker than the basic file.

Files to be received: full-size pdf with cut lines and 3 mm bleeds exported in 100% black (C0 M0 Y0 K100).

Thermorelief is a printing process that involves depositing a transparent resin powder on the ink previously printed in offset or letterpress. This powder then swells under the effect of heat, giving the printed motif or text relief and brilliance.

thermorelief

-

Several colors can be printed in thermorelief. However, this technique can only be used on one side of the paper. This process offers a more economical alternative to engraving.

Papers: uncoated from 90 gr to 400 gr

Files to be received: full-size pdf with cut lines and 3 mm bleeds, 1 page per color printed exported in 100% black (C0 M0 Y0 K100).

Offset printing is used to produce large print runs, in one or more colors and on a wide variety of papers. This printing technique does not allow for any relief, but gives also a finer character.

offset

-

Colors are obtained either from a pantone reference (PMS) or in four-color process (4 basic colors: cyan, magenta, yellow and black = CMYK).

Paper: from 90g to 400g, coated and uncoated papers that are “HP Indigo certified” can be used.

Files to be received: full-size pdf with cut lines and 3 mm bleeds, Pantone U colors for uncoated papers, C for coated papers or CMYK for four-color process offset printing.

Digital printing can be also used to produce multi-color prints. In comparison with offset, this process is advantageous for smaller print runs.

digital

-

However, if the format is too large, we have to use offset printing. The paper range is also smaller, as only certain papers are suitable for the HP Indigo machine.

Paper: from 90g to 400g, coated and uncoated papers that are “HP Indigo certified” can be used.

Files to be received: full-size pdf with cut lines and 3 mm bleeds, colors must be in CMYK.

slice staining

Edge coloring is generally carried out on thick cards and is one of Handley's specialties. The colors are varied. You can either stay with the same color as your print or use a second color to add contrast.

-

Paper: 300g to 900g. Edge coloring can also be carried out on uncoated paper. It is always best to carry out a test, as some papers are too absorbing and the ink penetrates too much.

To make your projects look even more special, we can cut it into different shapes. You can add pleats, flaps or rounded corners to your project, or go into a variety of shapes such as feathers, clouds or palm trees…

die-cutting

-

For each project, a form is created and carefully saved for future use. For even greater finesse, we recommend laser cutting.

Paper: from 90 g to 700 g.

Files to be received: full-size pdf with shape layout in 100% black.

-

1. getting in touch

Whether you already have a very specific project in mind or you're still in the dark, we'll be happy to help you. We can either receive your request by email or meet at our offices.

-

2. technical decisions

Together, we'll decide on the printing technique(s) best suited to your idea.

We'll define the paper and its weight, and choose the right colors. -

3. price quotation

Based on these elements and your initial estimate of quantities, we will provide you with a price quotation tailored to your needs.

-

4. graphic design

If you don't have a ready-to-use file, we also offer a graphic design service to make your greatest dreams come true. With 15 years’ experience in the printing industry, our graphic designer has a perfect knowledge of the various printing techniques and will be able to give you the best advice to create a project that suits you.

-

5. printing

Once the final design has been approved, the printing process can begin. Printing generally takes between 5 and 8 working days. Depending on the printing technique selected, a more precise timetable will be communicated to you when the final proof is accepted.

-

6. receipt of your printed project

Your order can be collected directly from the print shop, or delivered or sent to you (price and delivery time will be communicated according to the destination).